DG sets, short for diesel generator sets, are widely used to provide backup power in various sectors, such as industries, commercial buildings, and homes. In recent years, there has been a surge in the quest for more environmentally friendly and cost-effective energy solutions. One area of significant interest is the concept of using alternate fuels or a combination of fuels to power DG sets. In this context, the terms Bi Fuel and Dual Fuel frequently arise. Let’s delve into what they mean and the essential differences between them.

What Do You Mean Bi Fuel Systems

Bi-fuel systems enable a DG set to operate on two distinct fuels, but not simultaneously. This means the DG set can switch between the two fuels as the need arises, running on one fuel at a time.

Advantages of Bi-Fuel Systems:

- Flexibility in Fuel Choice: Users can switch between two different fuel types depending on availability, cost, or performance requirements.

- Extended Range (for vehicles): In vehicles, when one fuel type is exhausted, the system can automatically switch to the other, effectively increasing the range.

- Potential Cost Savings: If one fuel becomes more economical than the other, users can switch to the cheaper option, leading to savings.

- Environmental Benefits: One of the fuels in a bi-fuel system can be a cleaner-burning option, reducing emissions when used.

- Backup Option: In situations where one fuel type becomes unavailable, the system can rely on the other fuel, ensuring uninterrupted operation.

- Safety: In some applications, having a secondary fuel can be a safety feature, allowing operations to continue in case of one fuel supply disruption.

Disadvantages of Bi-Fuel Systems:

- Increased Initial Cost: Setting up a bi-fuel system, with its dual tanks, injectors, and other components, can be more expensive than a single-fuel system.

- Maintenance Complexity: Having two fuel systems can increase maintenance demands, requiring checks and balances for both systems.

- Space Consumption: In vehicles, especially, having two fuel tanks can consume more space, potentially reducing cargo or passenger space.

- Fuel Storage: Storing two types of fuels, especially if they have different storage requirements, can be challenging.

- Complexity in Operation: Some users might find switching between fuels or managing two fuel types cumbersome.

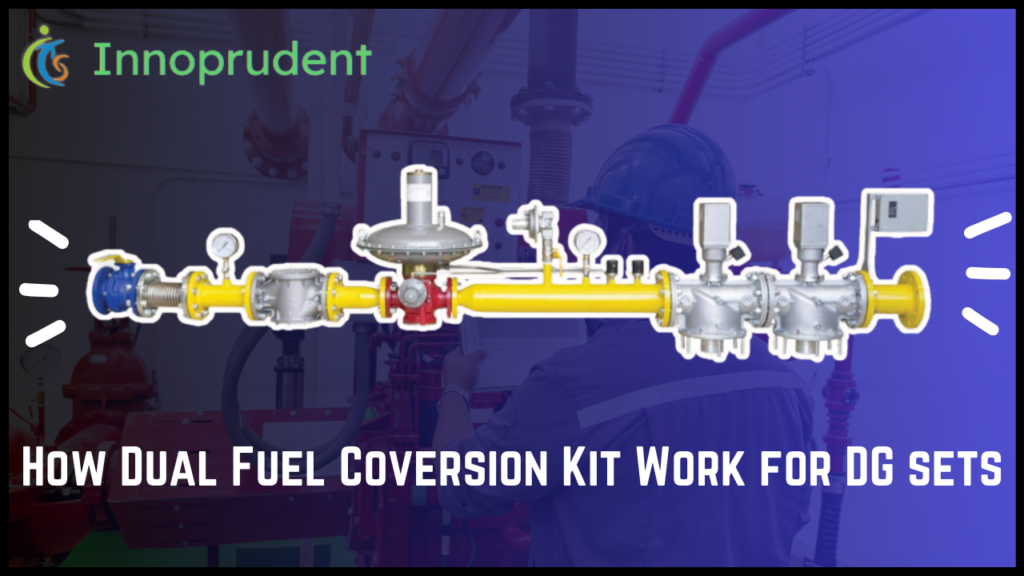

What Do You Mean Dual Fuel Systems

In dual fuel systems, the DG set runs on a mixture of two fuels simultaneously. Typically, a primary fuel (like diesel) is mixed with a secondary fuel (like natural gas) to power the generator. The proportion of each fuel in the mix can vary, but both fuels are always present during operation.

Advantages of Dual Fuel Systems:

- Enhanced Efficiency: Combining fuels can optimize combustion, potentially improving engine efficiency.

- Reduced Emissions: Mixing a primary fuel with a cleaner-burning secondary fuel can reduce harmful emissions.

- Flexibility in Fuel Ratios: The mixture ratio can be adjusted to optimize performance, emissions, or cost.

- Economic Benefits: If one fuel is more affordable, the system can be adjusted to use more of that fuel to save costs.

Disadvantages of Dual Fuel Systems:

- System Complexity: Managing the blending of two fuels in the right proportion requires a more complex system.

- Dependency: The system relies on the availability of both fuels. If one is unavailable, it might not operate at optimal efficiency.

- Cost: Dual fuel systems, especially with the technology to blend and optimize fuel mixtures, can be expensive.

- Maintenance: Regular checks are required to ensure both fuels are being mixed and burned efficiently.

When choosing between bi-fuel and dual-fuel systems, it’s essential to weigh these advantages and disadvantages in the context of the specific application and requirements.

Difference Between Bi Fuel and Dual Fuel Sets

| Aspect | Bi-Fuel Kit | Dual-Fuel Kit |

|---|---|---|

| Primary Fuel | Two separate fuel systems (e.g., gasoline and CNG). | Single primary fuel system (e.g., gasoline or diesel). |

| Fuel Switching | Driver can switch between primary and alternative fuel. | Primary fuel remains constant, with added alternative fuel. |

| Fuel Efficiency | Generally offers good fuel efficiency due to dual options. | Enhances efficiency of primary fuel with alternative fuel. |

| Fuel Availability | Provides flexibility when alternative fuel is scarce. | Relies primarily on the availability of primary fuel. |

| Emissions Reduction | Reduced emissions when running on alternative fuel. | Reduced emissions due to cleaner-burning alternative fuel addition. |

| Cost-Effectiveness | May require a dedicated bi-fuel vehicle or retrofitting. | Retrofitting option is often cost-effective. |

| Installation Complexity | More complex due to dual fuel systems. | Simpler installation integrates with the existing fuel system. |

| Common Alternative Fuels | Simpler installation integrates with existing fuel system. | Compressed Natural Gas (CNG), Liquefied Natural Gas (LNG). |

This table summarizes the key differences between bi-fuel and dual-fuel kits, highlighting their primary fuel systems, fuel switching capabilities, efficiency, emissions reduction, availability, cost-effectiveness, installation complexity, and common alternative fuels used.

Applications of Bi-Fuel Systems:

- Automotive: Many cars and trucks, especially in regions where certain fuels like CNG or LPG are popular, come with bi-fuel systems to provide flexibility in fuel choice.

- Generators: In places with inconsistent fuel supply, bi-fuel generators can switch between fuels to ensure continuous power.

- Industrial Equipment: Some heavy machinery and equipment that operate in varied conditions might use bi-fuel systems for flexibility.

- Remote Locations: In areas where fuel supply might be inconsistent or limited, having a secondary fuel option is crucial.

Applications of Dual-Fuel Systems:

- Marine Engines: Many large ships use dual-fuel engines, especially with the push towards cleaner fuels like LNG (Liquefied Natural Gas).

- Power Plants: Some power plants, especially in regions with varied fuel availability, use dual fuel systems to ensure consistent power generation.

- Industrial Burners: In industries where precise combustion control is crucial, dual fuel burners allow for optimal efficiency and emission control.

- Large Vehicles: Some heavy-duty vehicles, like buses or trucks, might use dual fuel systems to reduce emissions or take advantage of available fuels.

- Agriculture: Tractors and other agricultural machinery might use dual fuel systems for efficiency and cost-effectiveness.

Some Related Posts:

Wrapping Up:

Choosing between bi-fuel and dual-fuel for DG sets comes down to specific needs, availability of fuels, environmental concerns, and economic considerations. Both systems offer a move away from the sole dependency on traditional fuels, pushing towards a more sustainable and flexible future for power generation.

In the ever-evolving energy landscape, adaptability is key. Whether you opt for bi-fuel flexibility or the combined efficiency of a dual fuel system, the shift towards these alternative fuel systems is a step in the right direction for a greener tomorrow.

Frequently Asked Questions

Q1:- 1. What is the main difference between bi-fuel and dual-fuel systems?

Bi-fuel systems allow a device or vehicle to switch between two different fuels but not use them simultaneously. Dual-fuel systems, on the other hand, use a mixture of two fuels simultaneously during operation.

Q2:- What are the primary advantages of using a bi-fuel system?

Some advantages of bi-fuel systems include flexibility in fuel choice, extended range (for vehicles), potential cost savings, environmental benefits, backup fuel options, and safety in certain applications.

Q3:- What are the primary advantages of using a dual-fuel system?

Advantages of dual-fuel systems include enhanced efficiency through optimized combustion, reduced emissions, flexibility in fuel ratio adjustments, potential cost savings if one fuel is more affordable, and the ability to use cleaner-burning alternative fuels.

Q4:- In what applications are bi-fuel systems commonly used?

Bi-fuel systems are often used in automotive applications (cars and trucks), generators, industrial equipment, and in remote locations where fuel supply is inconsistent.

Q5:- What are some common alternative fuels used in bi-fuel systems?

Common alternative fuels in bi-fuel systems include Compressed Natural Gas (CNG) and Liquefied Petroleum Gas (LPG).

Q6:- Where are dual-fuel systems commonly employed?

Dual-fuel systems are commonly used in marine engines, power plants, industrial burners, large vehicles (such as buses and trucks), and in agriculture for tractors and machinery.

Pingback: What are the Benefits of Cummins Dual Fuel Sets? How is it Helping in Energy Efficiency? - Innoprudent

Pingback: Energy-Efficient Appliances: The Path to Sustainable Living - Innoprudent