Diesel generators (DG sets) have been the backbone of reliable power generation in various industries for a long time. However, the rising costs of diesel fuel and increasing concerns about environmental health have led to the development of many solutions. One such solution is the dual-fuel conversion kit, which allows Diesel Generator Sets to operate on both diesel and alternative fuels like natural gas. In this blog, we’ll explore how these dual fuel conversion kits work, what are their benefits, and why they are becoming so popular.

Understanding Dual Fuel Conversion Kits

Before going deep into the details of dual-fuel conversion kits, it’s essential to understand their components and what is their purpose.

A dual-fuel conversion kit is a set of components and technologies designed to enable a diesel generator to run on two different fuel sources – typically, diesel and natural gas. This conversion offers several advantages like –

- Cost savings

- Reduced emissions

- Increased fuel flexibility.

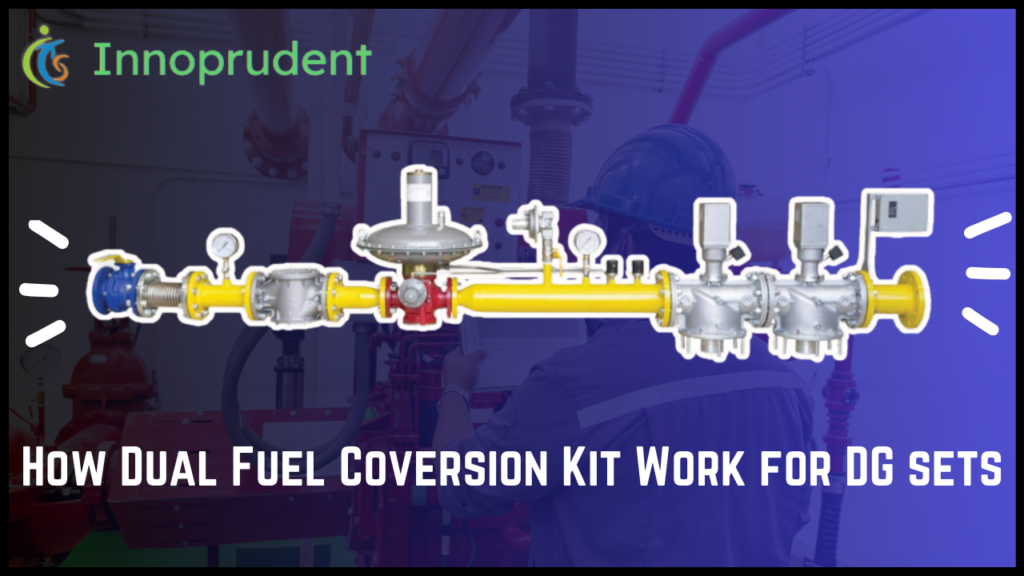

Key components of Dual Fuel Conversion Kit –

The key components of a dual-fuel conversion kit include:

- Gas Regulator: This component regulates the pressure of the alternative fuel (e.g., natural gas) to match the engine’s requirements.

- Mixer: The mixer blends the diesel fuel and alternative fuel in the correct proportions, ensuring efficient combustion.

- Dual-Fuel Engine Control Unit (ECU): This monitors engine parameters and adjusts the fuel mixture to optimize performance.

- Sequential Injection System: Dual-fuel systems use sequential injection, where diesel is injected first which is followed by the alternative fuel.

How Dual Fuel Conversion Kits Operate

Now that we’ve covered the essential components let’s see the operation and process of dual-fuel conversion kits:

- Fuel Mixing: The core of the conversion kit is the mixer, which combines diesel and alternative fuel in fixed ratios. This mixture is essential for maintaining engine efficiency and reducing emissions.

- Gas Supply: A fixed source of alternative fuel is needed, such as a natural gas pipeline, CNG tanks, or LNG tanks.

- Gas Pressure Regulation: The gas regulator ensures that the alternative fuel is delivered at the correct pressure for proper combustion.

- Dual-Fuel ECU: The ECU continuously monitors engine conditions, like load, speed, and temperature. Based on this data, it adjusts the fuel mixture accordingly to maximize efficiency.

- Sequential Injection: Many systems use sequential injection technology to introduce an alternative fuel after diesel. This process helps maintain engine performance.

- Safety Features: Conversion kits often include safety features, such as an automatic switch to diesel in case of alternative fuel supply issues, ensuring uninterrupted operation.

Benefits of Dual Fuel Conversion Kits

Now that we’ve covered how dual-fuel conversion kits work, let’s understand why they’re gaining so much popularity in the DG set industry:

- Cost Savings: The ability to switch between diesel and alternative fuels which are often cheaper can result in major fuel cost reductions.

- Environmental Benefits: Dual-fuel operation can reduce harmful emissions like nitrogen oxides (NOx), contributing to a greener and more sustainable operation.

- Fuel Availability: In regions where diesel supply is difficult or expensive, using alternative fuel sources like natural gas can provide a cost-effective and reliable option.

- Easier Regulatory Compliance: Dual-fuel generators often find it easier to work with strict emissions regulations, helping businesses avoid penalties and fines.

Installation and Maintenance

Proper installation and regular maintenance are critical for the successful operation of dual-fuel conversion kits. Engaging experienced professionals and sticking to manufacturer guidelines ensures safety and performance.

Installation:

- Professional Expertise: It’s highly advisable to enlist the services of experienced professionals for the installation of dual-fuel conversion kits. These technicians possess the knowledge and skills required to ensure an easy and safe integration with your generator.

- Compliance with Guidelines: Manufacturers provide specific guidelines for the installation of their conversion kits. Following these instructions guarantees that the conversion is performed correctly and in a manner that maintains the generator’s integrity.

- Safety Assurance: Improper installation can cause safety risks, such as gas leaks or fuel delivery issues. Professionals will conduct thorough safety checks and pressure tests to eliminate the main hazards.

Maintenance:

- Regular Inspections: Routine inspections are essential to catch any signs of wear, leaks, or malfunctions early. Check all kit components, fuel lines, regulators, and injectors regularly.

- Cleaning and Calibration: Keep components clean and ensure proper calibration of the dual-fuel system. This helps maintain the correct fuel mixture and efficient combustion.

- Fuel Source Maintenance: Pay attention to the quality of your alternative fuel source (e.g., natural gas). Ensure that the supply lines and storage containers are in good condition and free from contamination.

- Emergency Shutdown Checks: Verify that emergency shutdown mechanisms work as intended, providing a failsafe in case of any issues with the dual-fuel system.

- Compliance with Regulations: Stay informed about local regulations and compliance requirements related to dual-fuel systems. Regular maintenance helps ensure your system remains compliant.

By prioritizing professional installation and maintenance, you can take full benefits of your dual-fuel conversion kit. This approach not only enhances safety and reliability but also extends the lifespan of your generator while maximizing its efficiency.

Some More Posts

Wrapping Up

Dual-fuel conversion kits have emerged as a game-changer in the world of DG sets, offering cost savings, reduced emissions, and enhanced reliability. As technology continues to evolve, these kits are expected to play a pivotal role in powering industries while minimizing their environmental footprint. Embracing this innovation can be a sustainable and cost-effective choice for businesses looking to secure their power generation needs.

Frequently Asked Questions (FAQs):

- How much does it cost to install a dual-fuel conversion kit, and what factors affect the cost? Installation costs vary based on generator size, kit complexity, gas availability, and labor expenses. Consult a professional for a tailored estimate.

- Are there size limitations for generators that can use dual-fuel kits? Dual-fuel kits are available for generators of various sizes, but practicality depends on space and compatibility. Consult manufacturers and installers for feasibility.

- What are the maintenance requirements for dual-fuel generators? Regular maintenance includes inspections, cleaning, fuel quality checks, and emergency shutdown tests. Frequency varies, typically at least annually.

- What safety precautions are essential for dual-fuel generator operation, especially during fuel switching? Establish safety procedures, provide training, and follow manufacturer guidelines. Automatic switching to diesel in case of issues is crucial.

- In which industries or applications do dual-fuel conversion kits offer the most economic and environmental benefits? Dual-fuel kits benefit remote mining, data centers, and disaster-prone areas by reducing costs and emissions. Suitability varies, so evaluate each case.

How much does it cost to install a dual-fuel conversion kit, and what factors affect the cost?

Installation costs vary based on generator size, kit complexity, gas availability, and labor expenses. Consult a professional for a tailored estimate.

Are there size limitations for generators that can use dual-fuel kits?

Dual-fuel kits are available for generators of various sizes, but practicality depends on space and compatibility. Consult manufacturers and installers for feasibility.

What are the maintenance requirements for dual-fuel generators?

Regular maintenance includes inspections, cleaning, fuel quality checks, and emergency shutdown tests. Frequency varies, typically at least annually.

What safety precautions are essential for dual-fuel generator operation, especially during fuel switching?

Establish safety procedures, provide training, and follow manufacturer guidelines. Automatic switching to diesel in case of issues is crucial.

In which industries or applications do dual-fuel conversion kits offer the most economic and environmental benefits?

Dual-fuel kits benefit remote mining, data centers, and disaster-prone areas by reducing costs and emissions. Suitability varies, so evaluate each case.