Dual Fuel / Hybrid Solutions for DG Sets

CURRENT PAIN POINTS:-

- CAQM has banned DG Set to run on Pure Diesel.

- Production / Business is Affected when SEB Power Fails.

KEY FEATURES & TECHNICAL INFO:-

- Simultaneous Combustion of PNG as well as HSD

- Replaces Up to 70% HSD with PNG.

- No Modifications Required for Existing D.G. Sets.

- Seamless Switching of Fuels.

- Continuous Monitoring of Temperature & Pressure with Safety Provisions.

WHY SWITCH – VALUE PROPOSITION:-

- Compliance to CAQM.

- Proven, Reliable & Negligible Maintenance.

- Business Continuity, Faster ROI.

- Reduces Air Pollution.

What is Hybrid/Dual Fuel Solution ?

Hybrid/Dual fuel solutions have been Designed and Manufactured by A Division of Control Infotech manufactured to existing diesel engines into Hybrid/Dual Fuel.

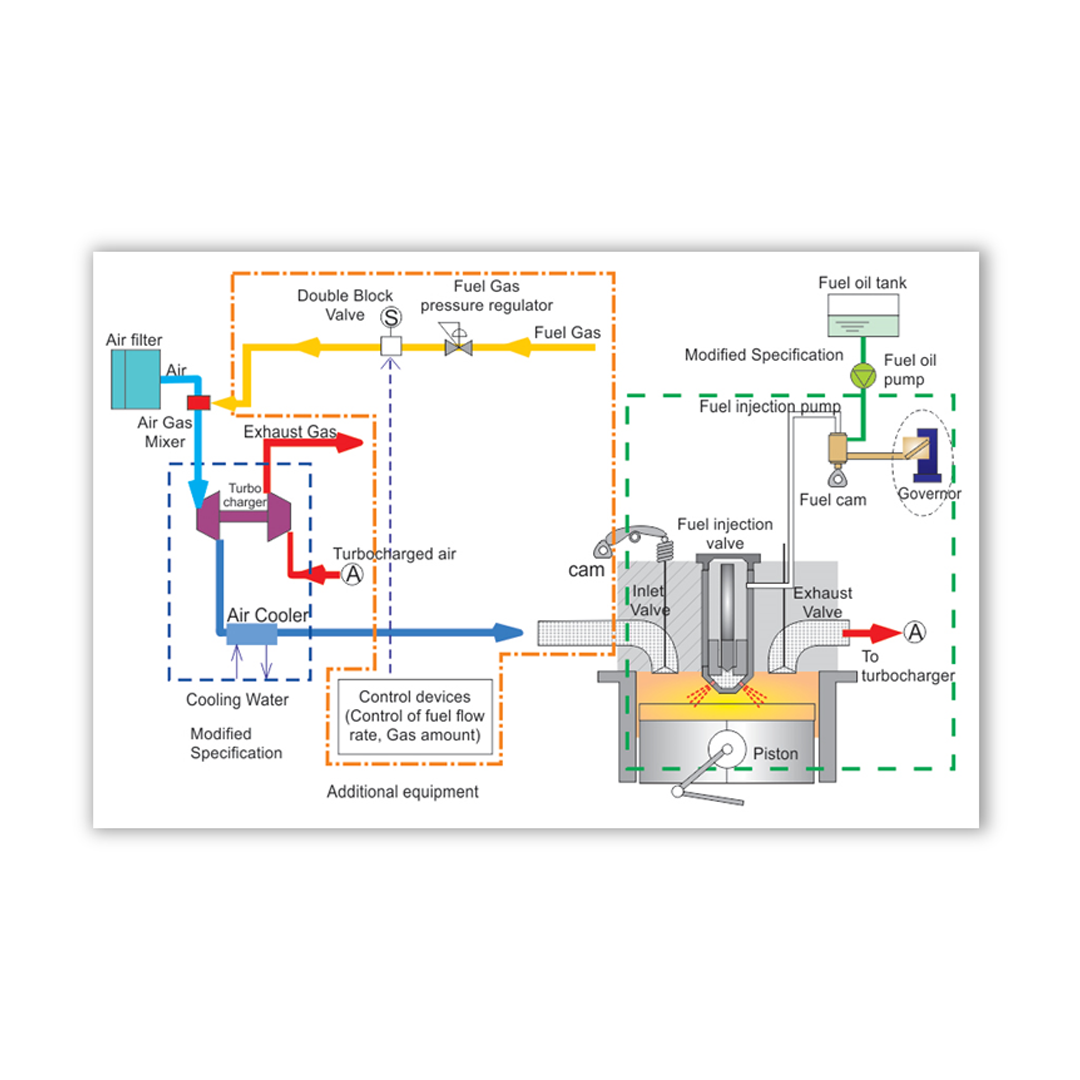

- Hybrid/Dual Fuel is the simultaneous combustion of two fuels; methane-based gaseous fuel is utilized in conjunction with diesel fuel to operate the engine. After conversion, the engine is able to operate on either 100% diesel fuel, or alternatively, on a mixture of diesel fuel and methane-based fuels. At no time is the engine able to operate on gaseous fuels exclusively.

- In Hybrid/Dual Fuel solution, reduced quantity of diesel fuel acts as the ignition source for the air-gas mixture in the cylinders and PNG provides the equivalent heat energy source required to operate the engine at different loads.

WHAT IS HYBRID/DUAL FUEL TECHNOLOGY?

- Hybrid/Dual Fuelling System is an innovative retrofit technology that allows liquid-fired engines to operate on a mixture of liquid fuel and Natural Gas. This is achieved through the use of technologies that are installed externally of the engine.

- Hybrid/Dual Fuel System delivers Natural Gas to the cylinders via Air-Gas Mixer located in the standard engine air-intake system. The Gas is then ignited by a diesel “pilot” that acts as an ignition source for the air-gas mixture.

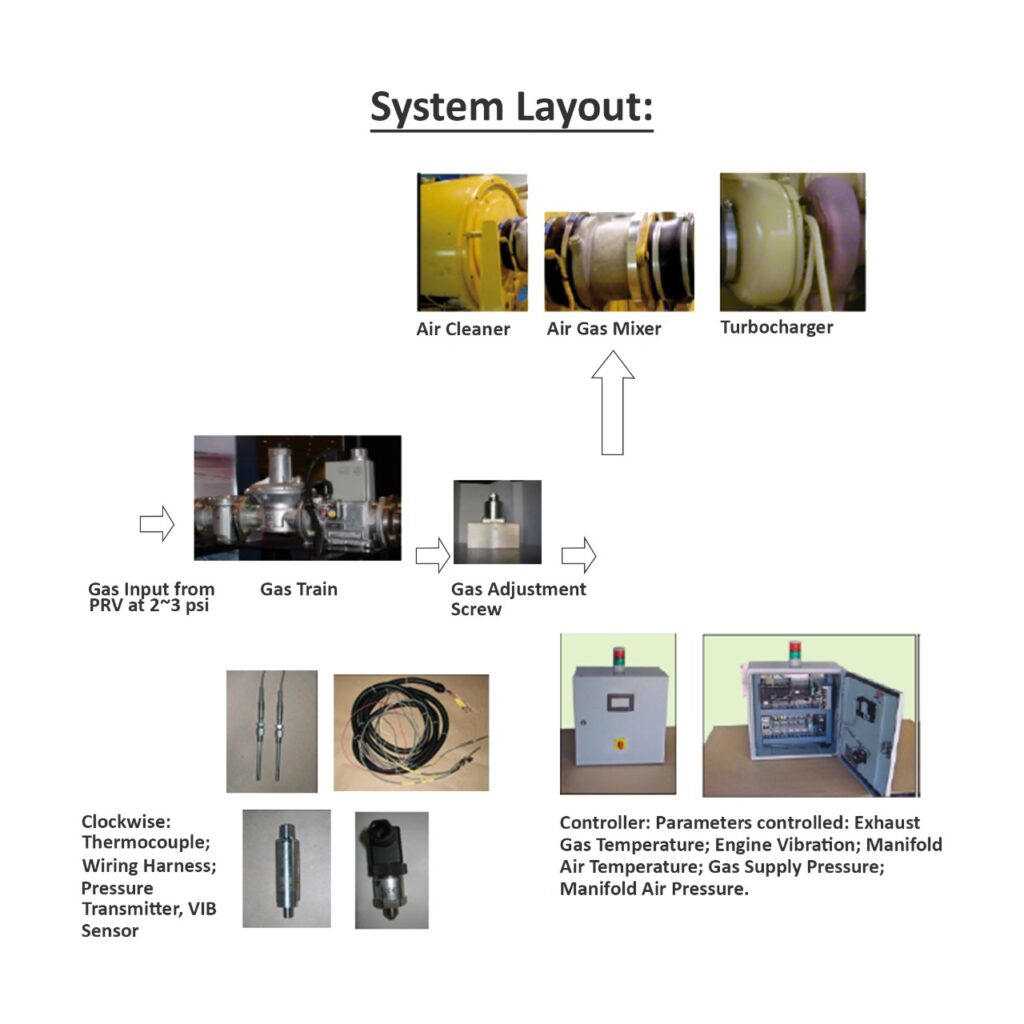

- The system requires precise regulation and control of the fuel supply gas. The Hybrid/Dual Fuel System is supplied with a “gas train” consisting of gas filter, zero pressure gas regulator and electrically activated gas solenoid valve. The gas train is designed to accept low pressure gas and supply regulated gas to the engine at slightly negative pressure.

- Hybrid/Dual Fuel solution has been designed for operation both on Manual and Automatic mode through the “State of Art Electronic Controller”. This has been done for ease of operation as per the availability of PNG etc.

- The State-Of-The-Art controller monitors critical engine and Dual-Fuel System parameters and activates/ deactivates gas mode according to programmed limits. It provides safety to the engine, while operating in the Dual-fuel mode.

- Conversion allows the engine to operate on gas mixtures ranging from 50% upto 70% + of total fuel consumed. Engines converted to Dual-fuel exhibit diesel-like performance in critical areas as efficiency, stability and load acceptance.

- The compatible Fuel Gases are – Pipeline natural gas (PNG); Coal-bed Methane (CBM); Compressed natural gas (CNG); Bio-gas (landfill, wastewater); Liquefied natural gas (LNG); wellhead gas.

- Hybrid/Dual Fuel solution has been developed as fully integrated solutions with critical components sourced from European suppliers like Dungs, Germany.

- In case of eventuality PNG supply is stopped, the sensors on sensing low PNG pressure gives signal to Controller and it automatically reverts the engine to 100% diesel operation irrespective of PNG settings or load condition.

- The Changeover from Hybrid/Dual Fuels to 100% Diesel Fuel is seamless and without effecting the operation of DG set and neither it requires action by the Engineer. When the PNG supply is resumed, then the Engine automatically reverts to its predefined settings of PNG+Diesel.

- Performance of DG Set in terms of Efficiency, Load bearing capacity, Stability, Reliability is not effected and remains the same as before.

What are the Hybrid/Dual Fuel System Characteristics:

- Non intrusive simple construction

- Available for different sized high speed engines

- Simple and easy to operate

- Safe engine operation by continuous monitoring of

- Exhaust Gas Temperature

- Engine Knock

- Institutes Fuel Flexibility – the engine continues to run, even if no gas is available, on 100% liquid fuel.

- Seamless switching from (Gas + Liquid) to (liquid) fuel and vice versa.

“Energy saved is energy earned. Let us work towards a sustainable world by embracing renewable energy.”

Our Achievements!!

WHAT ARE THE ADVANTAGES OF

HYBRID/DUAL FUEL SOLUTION ?

- Existing DG set can be used instead of buying new equipment

- No modifications are required to be done on existing engine or system

- Replacement of Diesel by PNG achievable upto 70% on standard test conditions & depending on load to meet the emission norms/statutory complainces

- Capital cost less than 3 times compared to Gas Engine

- Faster return on investment

- No moving components and low operations & maintenance cost

- No change in existing power output of engine

- Continous monitoring of PNG pressureand exhaust gas temperature for safe operation

- Flexibility of fuel combination between PNG & Diesel

- Seamless switching of fuel between PNG & Diesel without effecting plant operations

FREQUENTLY ASKED QUESTIONS

No. It does not effect the power output of the engine & power remains the same as before

No. Burning of PNG does not produce any large particulate residues. PNG prevent the build-up of heavy carbon deposits in the combustion chamber and exhaust system. Therefore the wear & tear inside the cylinder liner and ring is reduced. Eventually it leads to longer average intervals between engine overhauling.

Because there is no modification to the OEM controls, the generator set is able to revert back to running on 100% diesel without interruption of power if there is ever a loss of natural gas.

Yes, it will be able to handle changes in load because the system has dynamic control and operates flawlessly.

The Solution has been designed for 1500 RPM Engine speed applications from 150 KW up to 2.5 MW.

Engine heat rejection rates while operating are similar to 100% diesel operation. The engine exhaust gas temperature, coolant temperature, oil temperature and intake air temperature levels remain within the limits set by the engine manufacturer.

The system is governed with a control panel which is fitted with sensors and transducers. Our control panel is programmable to pre-fixed limits for safety for exhaust gas temperatures, engine vibrations, and manifold air pressures. Continuous monitoring of all engine parameters is carried out by the control panel and the moment it senses any variation in the pre-set limits, the solenoid valve is closed and the gas supply is cut off.